LC607 OLS – 3/8 in. x 70 ft. Light Duty Hose Reel

Reelcraft’s Series LC stainless steel hose reels are developed for light-duty, spring-driven hose reel applications in corrosive or sanitary environments. Designed for stationary indoor and outdoor use, these reels can be attached to most surfaces that can be drilled. The reel is built with high quality stainless steel components for maximum corrosion resistance. The four base slots allow the reel to be easily mounted or adjusted. The eight position ratchet locks the reel at the desired hose length while the guide arm adjusts to five convenient positions. **Series LC reels have a brass swivel.**

- Robust construction – Base and guide arm made of heavy-gauge steel stampings with reinforcing ribs

- Corrosion resistant – High quality stainless steel components

- Easy mounting – Base slots to facilitate mounting and adjustment

- Latch spring – Field-proven torsion spring, stainless steel construction

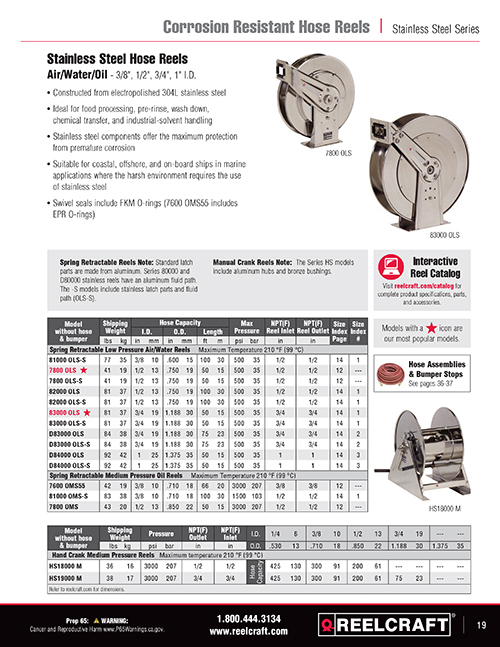

Reel Specifications and Dimensions

Additional information

| Weight | 35 lbs |

|---|---|

| Series | |

| Hose I.D. | |

| Hose O.D. | |

| Hose Length | |

| Pressure | |

| Inlet | |

| Reel Outlet | |

| Hose Included | |

| Max Temperature | |

| UPC | 699567012917 |

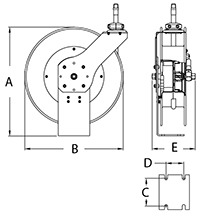

| A | 20.5" |

| B | 19.375" |

| C | 4.75" |

| D | 3" |

| E | 8.125" |

Parts

Bumper Stop

Tech Bulletins

FAQs

How do I increase or reduce spring tension?

To increase spring tension:

Adding wraps of hose will increase spring tension. This can be accomplished by pulling out approximately 10 feet of hose, hand feed hose back up through roller bracket assembly* until loop is large enough to slip over spool. Add two or three wraps until desired tension is achieved. Do not exceed spring capacity.

To reduce spring tension:

This can be accomplished by removing wraps of hose from the reel spool. Remove wraps of hose from the sheave, one wrap at a time, until desired tension is obtained.

*For dual pedestal reels, you will have to remove the bumper and control handle then feed the end of the hose through the roller bracket assembly to add or remove wraps of hose from the reel drum.

Can my spring driven reel be made constant tension?

Most Reelcraft spring retractable reels can be made constant tension by removing the latching system. There are some models that may not have this capability.

Please refer to our online tech bulletins for more information on converting your reel to constant tension.

Why is my air pressure or fluid flow restricted?

U-bolts tightened down too tight on the hose restricting product flow. Loosen U-bolts to be snug on the outside diameter of the hose, but not too much that it crimps off product flow.

Why will my hose reel or cord reel not retract?

Insufficient Spring Tension

Adjust the spring tension by adding wraps of hose. Pull out approximately 10 feet of hose. Hand feed the hose back up through roller bracket assembly until the loop is large enough to slip over sheave. Add two or three wraps until desired tension is achieved. Do not exceed spring capacity. Watch our “How to Adjust Spring Tension” videos on our Technical Videos page for more help.

Hose / cord reel mounted on ceiling above 16 feet

Must special order heavier gauge spring steel for drive spring to overcome weight of hose / cord extending from reel. Control handle weight must also be considered. Contact Reelcraft for further information.

Latch mechanism engaged with drive spring coiled to solid height

U-bolt hose clamps on sheave assembly not positioned correctly.

Hose / cord fully extended will not retract

Latch mechanism engaged with drive spring is coiled to solid height. U-bolt hose clamps on sheave assembly are not positioned correctly.

Product supply to reel, rigid, plumbed in

If a flexible connecting hose is not used between hose reel inlet and hard plumbing, you stand the chance of causing excessive bind to main shaft and hub bearings causing reel not to retract. This will also void the warranty.

Reel mounted on uneven surface

Bolting the reel down to an uneven surface will distort the side frames causing a bind on main support shafts and restricting smooth retraction of the hose.

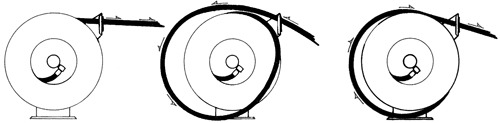

Wrong guide arm position

If the guide arm is in side wind position for ceiling mounted reels, the hose / cord is bending at a 90° angle over roller bracket assembly. This can cause excessive loss of spring tension. Adjust the guide arm to coincide with how the hose / cord reel is actually mounted. U-bolt clamps may also need to be adjusted.

Broken main spring, broken spring arbor, corrosion on shaft and hub

Replace broken part with new. For corrosion: disassemble reel and remove corrosion, lubricate and reassemble.

Why is fluid or air leaking from my swivel?

O-ring worn out or wrong O-ring for material being handled

Replace O-rings with O-ring kit or replace with correct rings for material being handled.

Swivel may be loose or not enough pipe thread sealant on shaft threads

Remove swivel and check threads ensuring they are in good condition. Reapply thread sealant and install swivel onto reel ensuring good thread engagement.

Why will my reel not latch?

If your reel will not latch, it could mean the latch spring is broken or the latch pawl or latch plate is bent. The broken or bent part(s) will need to be replaced.

Refer to our Service Manuals page for assistance finding your parts.